Cement mill Wikipedia

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ...

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ...

ball mill design,ball mill manufacturer for sale in india . Highperformance systemsfor wet grinding applications. The comprehensive range of wet grinding systems ...

Ball Mill Application and Design. ... an expert at Paul O. Abbe to help you determine which design and size ball mill would be best ... and Field Service;

SUMITOMO KAGAKU 2007II 2 Design Method of Ball Mill by Discrete Element Method of the balls are in a state where they are covered with the solid materials.

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

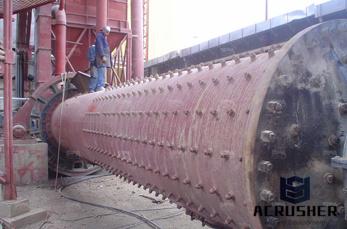

What is a Ball Mill? A ball mill is a type of grinding mill, purposed similarly to the sag mill or other mining crushers. These machines are used to grind or mix ...

A ball mill for powerful size reduction and homogenization. RETSCH ball mills are available as mixer mills as well as planetary ball mills.

new design ball mill aluminum grinding,US 20,000 72,000 / Set, New, Ball Mill, AC from Zhengzhou Jiangtai Heavy Industrial Machinery Co., Ltd. on ...

Ball Mill Design Pdf, Wholesale Various High Quality Ball Mill Design Pdf Products from Global Ball Mill Design Pdf Suppliers and Ball Mill Design Pdf Factory ...

What Is Ball Mill And Its Working Principle? The usage of ball mill and its technical data Ball mill is widely used for grinding ores and rocks in metal and nonmetal ...

Autogenous mills, semiautogenous mills and ball mills for wet grinding. ... provide process engineering design layout, ... Ball mill in iron ore bene ...

Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant ... quantify ball mill design parametersto reduce energy requirement for clinker grinding ...

PATTERSON''s unmatched Ball and Pebble Mill custom design experience and manufacturing ... PATTERSON Batchtype Ball Pebble Mills. ... Ball Mill without ...

Grinding in Ball Mills: Modeling and Process Control Vladimir Monov, Blagoy Sokolov, ... The design of a ball mill can vary significantly depending on the size, the

Ball Mill Mechanical Design; Roasting Ball Mill Grinding; ... GNR Services provides precision kiln alignment services and sells Kiln OEM Parts Ball Mill Service and ...

· RecrystallizedRocket. Loading ... Ball Mill Critical Speed Working Principle Duration: 5:40. 911 Metallurgy Corp. 78,358 views. 5:40.

The Selection and Design of Mill Liners . Malcolm Powell*, ... High–low double wave ball mill liners – These are a refinement of the wave liner, Figure 5.

CHANGSHA TIANCHUANG POWDER TECHNOLOGY CO., LTD. is one of largest professional manufacturers in China engaging in design, manufacture, and sales of all .

New Design Aac Ball Mill With Best Service From Yigong Machinery, Find Complete Details about New Design Aac Ball Mill With Best Service From Yigong .

Notes on Ball Mill Design Energy Required for Comminution. Feed material is assumed coarse hard rock. Feed Size and Product Size are 80% passing mesh sizes (micron)

Hence a rod mill generally precedes a ball mill in a ... Mineral Processing Plant Design ... For more information on mill suppliers search for grinding mills in ...

Ball Mill Manufacturers and Companies. ... Any ball mill company can design, ... Our dependable solutions are supported by our highly trained service department.

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index ...

Union Process has the experience and expertise to mill ... Choosing the Right Laboratory Ball Mills; Conventional Ball Mill ... Union Process provides Toll Milling ...

WhatsApp)

WhatsApp)