Theory and Practice for U. S. Stoneware

Theory and Practice for . Jar, Ball and Pebble Milling . ... easy loading and ... recommended when the grinding media charge is below 45 percent of the mill volume.

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Theory and Practice for . Jar, Ball and Pebble Milling . ... easy loading and ... recommended when the grinding media charge is below 45 percent of the mill volume.

THE GRINDING CHARGE OF ROTARY MILLS ... in the mill is presented,to achieve grinding in the best conditions ... in which Vgol means the volume of emptiness,

Mill Loading Guidelines. Mills are referred to by their total volume and also by their working volume. Generally, a mill''s working volume is 25% of the total volume.

at a ball charge of 8% volume, ... at a load of 26% total volume. SAG mill ... and structural loading. Once determined, increases in ball charge level above 14 ...

Search formula to calculate ball mill volume loading to find your need. . ball mill efficiency calculations . single toggle jaw crusher zenith; Click Chat Now.

Mill volume load. See infographic here: The Cement Grinding Office. The Art Of Sharing and...Imagination. Home; About Us; Services. Grinding Software; Consultancy;

Ball Mill Loading (dry milling) When charging a ball mill, ... so you may have to add more solids and check the solids volume again after a few hours.

_Survey_Sample_Grinding_CircuitsGMSGICEv01r02 Methods to survey and sample ... Autogenous Grinding (AG) mill, Ball mill, Comminution,

Effect of Slurry Density on Load Dynamic and Milling Performances in an Iron Ore Ball Mill Online Estimation of Inmill Slurry Density. Comminution Conference 2012 ...

How to Handle the Charge Volume of a Ball Mill or Rod Mill. ... The percentage loading or change volume can then be read off the graph in Figure 3 or can be ...

COPPER MOUNTAIN: OVERVIEW ON THE GRINDING MILLS AND THEIR DUAL PINION MILL DRIVES ABSTRACT ... Operating mill ball charge 15 percent by volume

how to calculate ball mill efficiency. How To Caculate Ball Mill Capacity. calculation of production cost stone crusher indonesia How To Calculate Crusher Running ...

polyethylenebased small bottle container (nominal volume of ... based on a laboratoryscale wet ball mill. Also, the effect of powder loading on the particle size

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ... steel balls in a ball mill, ... Let Jt be the fraction of the mill volume that is occupied

volume of ball mill calculations – Gold Ore Crusher. formula to calculate ball mill volume loading; calculation of the power draw of dry multi compartment ball ...

Calculate Circulating Load Ball Mill ... volume loading charge calculation for cement mill –RB Crusher Mill. formula to calculate ball mill volume loading ...

The optimum composition of the makeup ball sizes in ball mills is presented. • The effect of various factors was investigated via a grinding circuit simulation.

Fill levels for various ball mill applications. Media and Product Ball Mill Loading ... product is loaded into the mill. Mills can be loaded by volume or by weight ...

BallTube Mills This type of mill consists of a rotating tube filled with cast alloy balls. Coal is introduced ... A 20% reservoir volume per minute flow

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill ...

At the same time it was determined that the ball mill feed (cyclone underflow) contains 25% passing 75 um, and the mill discharge contains 45% passing 75 um.

MILL POWER FOR CONICAL (HARDINGE) TYPE BALL MILLS AUSTIN§, W. HILTONt and B. HALLt § Mineral Engineering Department, The Pennsylvania State .

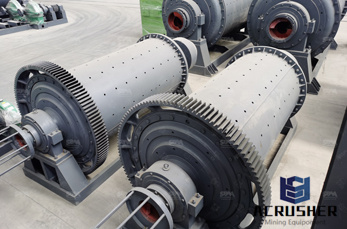

A ball mill, a type of crusher, is a cylindrical device used to grind chemicals or mix compositions. Ball mills rotate around a horizontal axis, partially filled with ...

We can calculate the steel charge volume of a ball or rod mill and express it as the % of the volume within the liners that is filled with grinding media.

WhatsApp)

WhatsApp)