Design And Evaluate Of A Small Hammer Mill

DESIGN AND EVALUATE OF A SMALL HAMMER MILL 482 for harvesting transporting and drying. Hill and Pulkinen 1988 and Samson et al. 2000 studied the macroperformance of grinders for hammer

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

DESIGN AND EVALUATE OF A SMALL HAMMER MILL 482 for harvesting transporting and drying. Hill and Pulkinen 1988 and Samson et al. 2000 studied the macroperformance of grinders for hammer

The simple grinding structure and short residence time reduce exposure of the materials to high temperatures. This makes the Feather Mill a suitable grinder for a wide variety of materials including heat sensitive materials. The pressure loss of the machine is very low making it easy to incorporate the machine into any process line

Hammer mill Grinder is something that has its use in shredding and crushing aggregate material in small pieces so that waste can get disposed of easily. These are the machines which coverts material into smaller pieces with the help of continuous blows of a hammer

202054Material of the proper sie goes on to the next step in the refinement process. Ethanol production also uses dry grinding but it has a longer process that has many steps in common with wet grinding. After the corn is broken down often through machine force in a hammer mill it goes into a storage chamber where it is kept wet. This allows the

DESIGN AND EVALUATE OF A SMALL HAMMER MILL. manufacturing and evaluate of a small crushing machine suitable . The process was repeated for samples of weight 4kg and 6kg

Today this process uses automation to hammer and control each point of impact. An electronicallycontrolled hammer head produces machinehammer peening and a CNC machine or a robot controls the head positioning executing CAM software that is programmed specifically for peening applications

A wide variety of glass recycling machine options are available to you There are 1287 suppliers who sells glass recycling machine on mainly located in Asia. The top countries of suppliers are China Japan and Taiwan China from which the percentage of glass recycling machine supply is 98 1 and 1 respectively

201485Small grain hammermills can be operated on current. Large hammer mills used in automobile shredders may be driven by diesel or electric motors ranging from 2000 to over 5000 horsepower The screenless hammer mill uses air

It should be no surprise that an automobile with a gasoline engine is a complex machine made of thousands of simple machines. Inside the engine each rocker arm that operates the many valves is a lever. The timing belt is a type of pulley and the car rides on four wheels mounted to two axles

202055Some of the more difficult materials to mechanically process are plastics rubbers and fibers because they deform but do not fracture when struck. One solution is cryogenic milling in which liquid nitrogen or carbon dioxide is injected with the feed to a hammer mill. The extreme cold makes plastic materials brittle enough to fracture easily

MACHINING OPERATIONS AND MACHINE TOOLS. 1. Turning and Related Operations. 2. Drilling and Related Operations. 3. Milling process in which a singlepoint tool remove material from the surface of a rotating work piece. Lathe Bedtype Mill

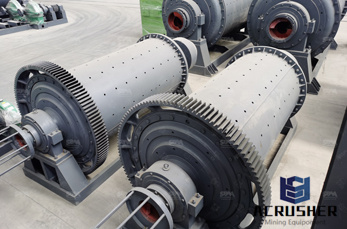

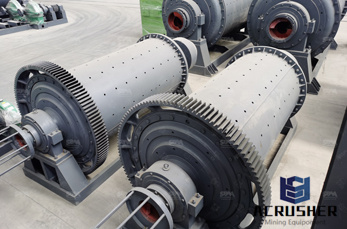

MRD MRE ball mill . Individual ball mills proven since 1864 . Simple and rigid design wear resistant lining minor maintenance requirement. In case of coarse grinding where a downstream screening machine is provided the product fineness can be preselected by providing a specific mesh width on the screening machine

In our glossary we try to provide this information to new users to be able to get a quick and simple introduction to the process of feed milling. The diagram below shows a rough guide to the layout of a feed mill. This feed mill could range from anywhere from 2th up to 10 th

Small pellet plant refers to the complete pellet plant has capacity range from 50khh to 1100kgh. As for the application small pellet plant is used to make wood pellets or animal feed pellets. Generally small pellet mill is the main equipment of small pellet plant and flat die pellet mill and small ring die pellet mill are both available

This webpage is best printed in Landscape format. This information was originally compiled by the US Army. Presented to you free by American Machine Tools Company. Milling is the process of machining flat curved or irregular surfaces by feeding the workpiece against a rotating cutter containing a number of cutting edges

The Doris Hammer Mill is simple and sturdy in construction. It is suitable for Grinding of Vegetable Products Minerals and Chemicals etc. The Mill can virtually handle any product. Hammer Mill are most effective method of Crushing Grinding or Pulveriing in a single Machine

You get a lot of powder with larger deviation from the hammering. A roller mill uses cylindrical rollers that grind the grain when it goes through them which requires less horsepower then a similar capacity hammer mill. A roller mill gets a more consistent grind and smaller deviation then a hammer mill by rolling the grain instead of hammering it

iMvubu Mill is a newly established company registered in November 2009. iMvubu Holdings Limited is a They also process such high volumes that quality is often neglected. Smaller outlets are typically small diesel powered milling units called hammer mills or

202043Mixing is the key process in poultry and cattle feed production to guarantee the final feed quality. In the mixing process the feed materials will be mixed according to the proportion. Pellet Mill This small animal feed line uses ZLSP 300 or ZLSP 400 type feed mill machine which is one of our hot sale flat die pellet mill

Sometimes we need to process them at first according to the production requirements. A hammer mill may be used to make the materials have the same particle sie. The length should be less than 6mm. The particle sie effect the efficiency of pellet making. Uniform in sie can clocked the machine sometimes

Advantages of Using FANWAY Automatic Feed Pellets Packing Machine The accuracy of the weighing and packing of feed pellets will directly affect the reputation and economic benefits of the feed pelleting factories. The automatic packing machine has higher accuracy lower labor intensity and much more efficiency than ordinary types

To make alfalfa pellets the first and most important thing you have to own is an alfalfa pellet mill. If you want to make pellets for sale the machine with large yield will be suitable. But if your goal is for own use a small alfalfa pellet machine can meet your need. RollerRotating Alfalfa Pellet Mill

202051It can be used together with various types of Jet Mill Impact Mill and Classifiers can design and equipments for vacuum conveying quantitative dosing dustfree feeding iron removal automatic packaging and other units according to requirements of the powder process

201965Oil Pressing Section. Oil pressing sometimes we called expeller pressing is the way for extracting oil from oilseeds. The process of oil pressing by using oil press machine is relatively simple with less supporting oil mill machinery. Only one oil press is needed to finish the oil pressing process

WhatsApp)

WhatsApp)